Cober Team

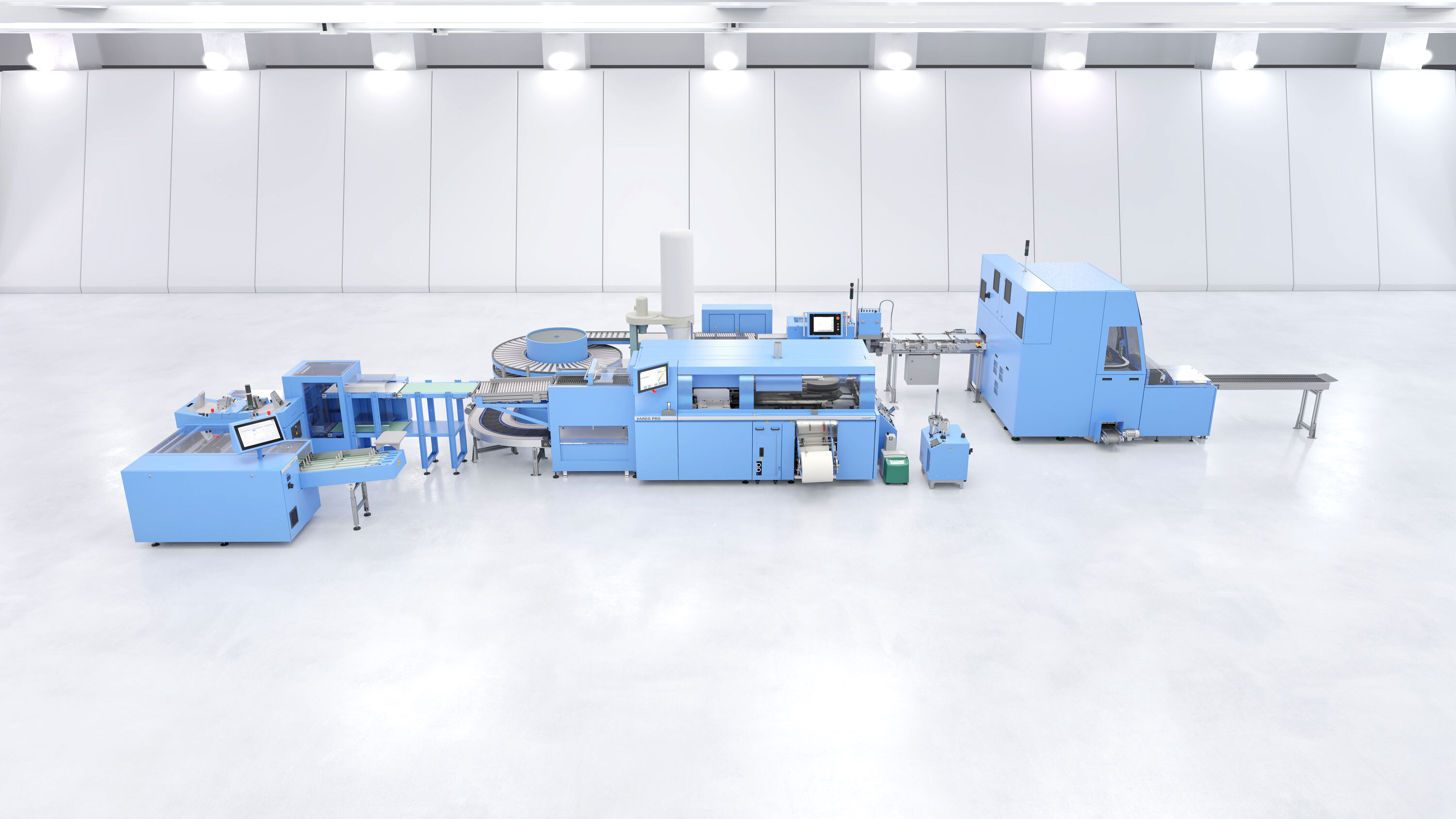

Cober is the first company in North America to implement Heidelberg's industry changing Plate to Unit device, which operates in tandem with our newly acquired Speedmaster XL 106 offset press.

With a history of investing in the newest technology, we are excited to install the first Plate to Unit in production in North America.

This new unit allows us to achieve consistently high productivity regardless of run length. We do a lot of short runs with high page counts that require a large amount of makereadies every day. Platemaking was becoming a bottleneck for us.

—Todd Cober, President, Cober Solutions

Bottlenecks will be eliminated thanks to the new and fully automatic printing plate logistics at the press. With Plate to Unit, ready to hang plates are provided and removed using a fully automated process. In addition to reducing the operator’s workload, the automation increases the reliability of plate changes and reduces the risk of scratches on the plate, which can cause paper waste..

The most intelligent Speedmaster yet allows us to continue to offer cutting edge innovative solutions to our clients.

We are excited about how this technology helps our team keep up with the ever increasing demands on short run, high quality, quick turnaround press runs. It means we are able to do plate change-overs in minutes, enabling our press operators to focus on what they do best...focusing on quality, and feeding the press with paper at 18,000 sheets per hour!

—Sam Mueller, Director of Manufacturing

.jpg)